Key Takeaways

- Streamlining optimizes the organization’s day-to-day operations.

- Address bottlenecks in the manufacturing operation to enhance productivity.

- Embrace automation technology to reduce human errors.

- Invest in staff training to ensure efficient role execution and high productivity.

- Optimize the supply chain for the effective flow of products and to minimize disruptions.

Looking to streamline your manufacturing business?

Streamlining can enhance productivity, make work easier for your team, increase output, and reduce costs, among many other benefits. It can be challenging though, and making changes to your operation can cause disruption.

Therefore, it is significant to go about it in the right way, and there are a few steps to take for its efficiency without causing too much disruption. Here are a few of the main steps that should make a positive difference and improve the daily running of the organization.

The first step is to evaluate your current processes. You should map out each process so that you can get a complete insight into what is required in every single step.

When you can do this, you can begin to see where the inefficiencies are and then find ways to make improvements to each method.

After doing this in every single task, even seemingly minor changes can have a big impact on the overall efficiency of production.

Leading on from this, one always needs to address the bottlenecks in the manufacturing operation if they want to streamline. You could make amendments elsewhere, but if these issues are not addressed, they will always hold you back.

This is why the initial step should be to identify bottlenecks and then find the best ways to resolve these issues – this should make a big difference to productivity and make work a lot more effortless for your team.

A smart manager will also understand the value of encouraging idea-sharing when it comes to the smooth running of the organization. Your employees are the ones that are tasked with carrying out each task and process, so you will find that they often have interesting ideas that can enhance the flow of work each day.

They might be aware of issues that you are unaware of and have ideas for how to resolve bottlenecks. This helps bring different viewpoints and ideas to the table, plus it can also help your staff to feel valued and an important part of the team.

These days, you should be automating manufacturing operations as much as possible. You will find that many repetitive tasks can be automated with online tools, software, and robots, and this should be embraced.

Automation is one of the best ways to optimize and can avoid human errors while also freeing up time for employees to focus on other areas of their roles.

It can provoke distress among employees, but once they see that it can be used alongside a human workforce and make their jobs trouble-free, it should be a piece of cake to implement and keep your staff happy.

Do You Know?

According to Statista, with automation and streamlining current business operations, 48% of firms have lowered their operating expenses.

It involves the use of machinery and equipment daily, so you want to make sure that you are utilizing the best equipment available. For those in the processing industries, specialized sight glasses can be helpful for smooth production.

Sight glasses enable the visibility of fluids and media in tanks and pipelines through a transparent window, and this can help with the workflow in several ways. There are different types of sight glasses, and they can be used in a few ways, including the ability to verify the production stages of a process.

You will want to make sure to get the right type of sight glass for your specific task. Make sure to get your equipment from a trusted supplier.

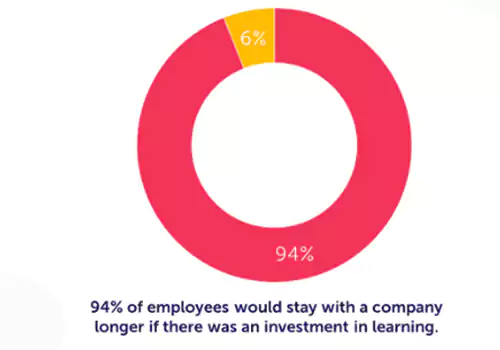

One needs to have the right tools, technology, and equipment in place, but also need to make sure that the employees know how to carry out their roles efficiently. This is why staff training is so significant when it comes to streamlining the operation.

You should provide ongoing training for your team and encourage them to come forward if they have any concerns. Besides training, you should also know how to motivate your team and keep them happy.

Investing in staff training will maintain high productivity levels and avoid staff turnover.

Another positive step is to improve its layout. Many enterprises are set up in one way and never change the layout, which could be holding you back from increasing capacity. There is a probability that it can make matters worse by changing the layout, so you need to be cautious and think carefully.

Only make the required changes that deliver positive results. Brainstorm ways to simplify work for your employees by improving the layout, and you should notice an uptick in productivity.

Make sure to think about the suppliers. You could have a slick operation in place, but if you have issues with your supply chain, it can cause disruption and slow everything down. Therefore, you want to optimize your supply chain so that it can brush up the flow of products and keep everything running efficiently at all times.

Many firms have been struggling with supply chain issues since the pandemic, so you may want to check out ways to develop a more reliable supply chain if you have been encountering issues lately.

As discussed these steps will guide you in streamlining your manufacturing operation. It would do good for the organization, but it is also a challenge and one that can disrupt if you change too much at once.

Following these steps will help you in making smart improvements to your daily action and minimize disruption so that positive results can be seen straight away. Hopefully, this will increase productivity, make work easier for your team and boost the success of your business.